Top in every discipline

Metalworking

The FLEX range for professional metalworking

FLEX has the most extensive range for the metalworking professional From universal products such as angle grinders and straight grinders to band saws and circular saws and many special products such as burnishers and pipe belt sanders.

Whether metal construction, locksmithery, railing construction, sanitation engineering, tank construction, plumbing or shipbuilding - FLEX offers tools of every kind for metalworking and the right product for every job. Surface finishing, metal cutting, metal grinding etc.: Metal professionals can rely on FLEX in any situation.

Angle grinders from the original

The real FLEX

In 1954, FLEX (then still Ackermann + Schmitt) launches the first high-speed angle grinder on the market. The first FLEX. And to this day, FLEX angle grinders still impress with their powerful motors, user-friendly features and perfect ergonomics: Great working comfort and safe tool guidance - with significantly more power. Because we know what makes the perfect angle grinder.

Just real proformance. With the real Flex.

Metal surface finishing

Whether you're polishing metal or stainless steel, brushing metal or stainless steel, grinding metal or stainless steel, burnishing metal or stainless steel: Metal surface treatment is easily possible with FLEX products.

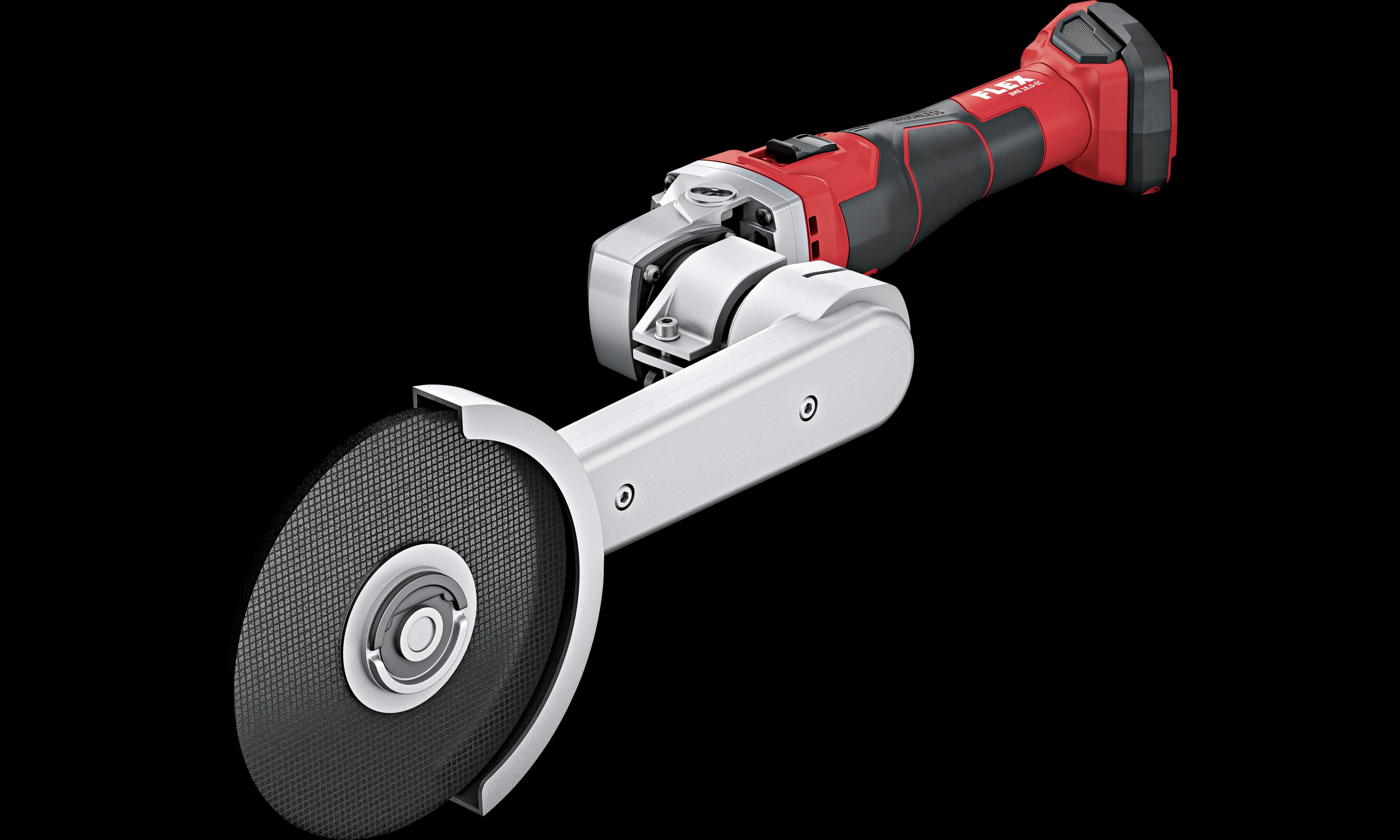

SUPRAFLEX

Cordless and with a cable

The SUPRAFLEX is the specialist grinding tool for stainless steel and metal. The ergonomically-shaped handle cover with its soft grip allows the user to guide the machine safely and precisely. The SUPRAFLEX is available in corded and cordless versions for greater flexibility.

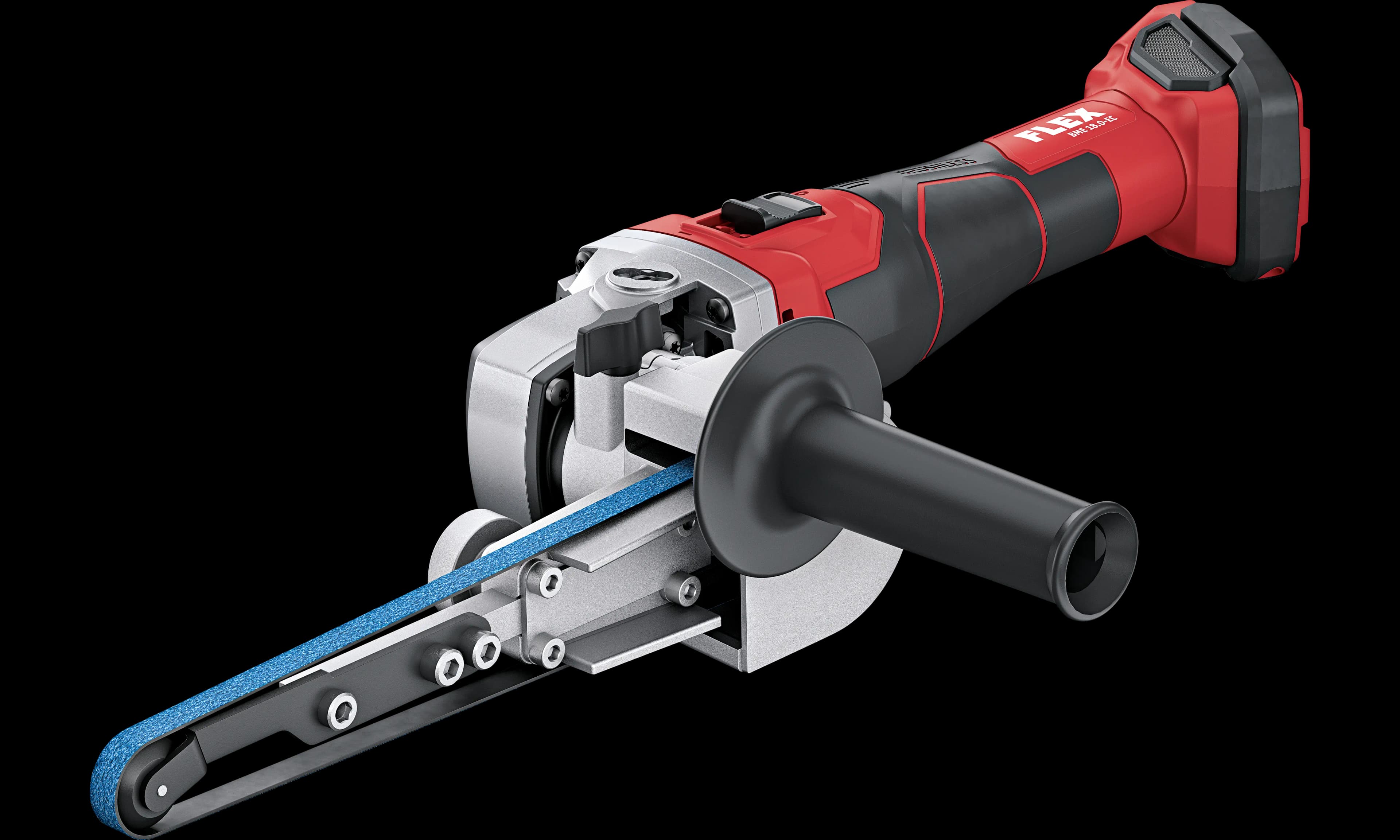

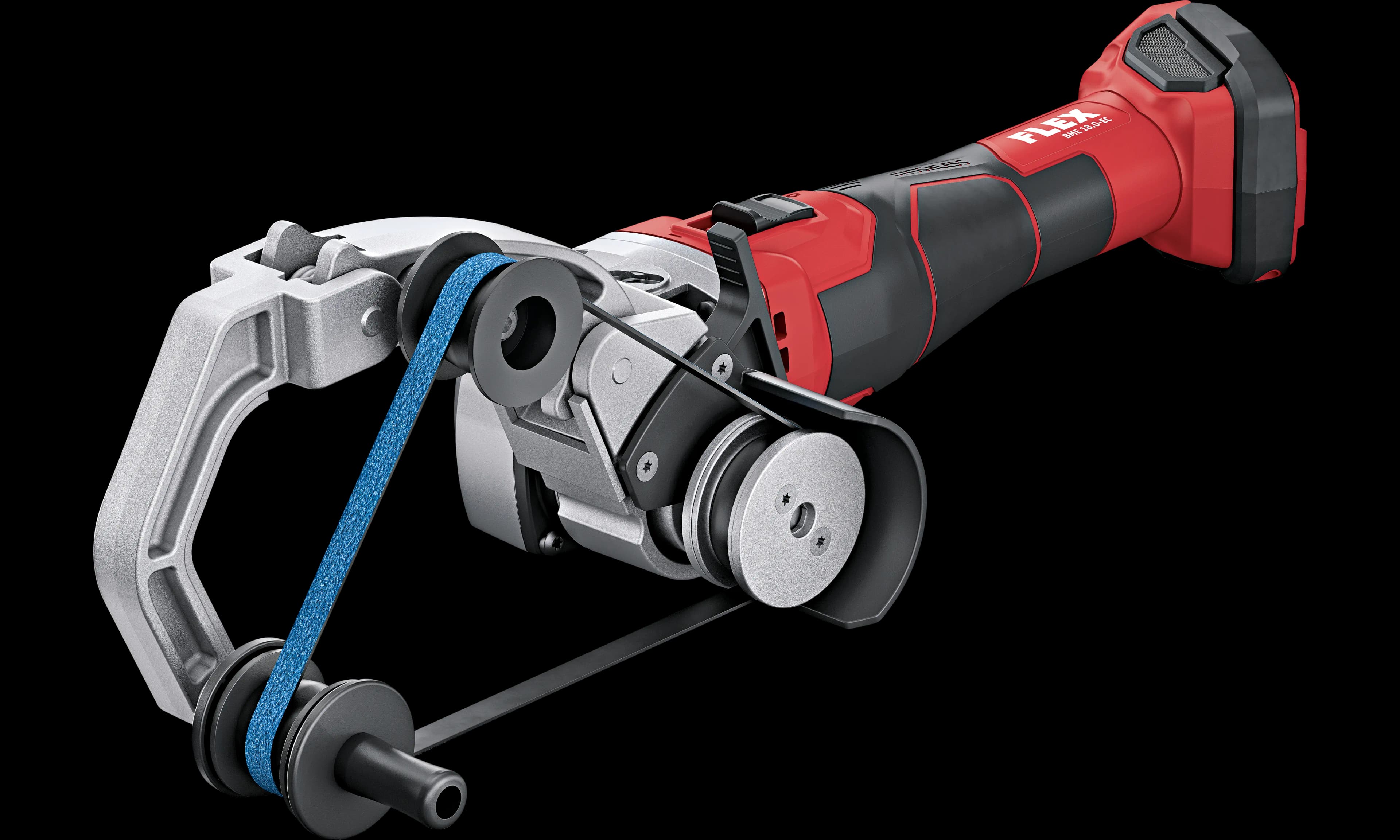

Metal grinding system

Cordless and with a cable

FLEX offers a variable surface system for working on metal and stainless steel. The burnishing machine, fillet weld sander, pipe belt sander and belt file allow a wide variety of applications from deburring metal to polishing metal, to burnishing, smoothing or brushing stainless steel and metal. The TRINOXFLEX basic motor with the four attachments offers maximum flexibility, as all applications can be covered with one machine. The individual machines are ideally suited for specialists in the applications.

Cutting metal without flying sparks

FAQ

What are the fundamentals of metalworking?

Extensive basic knowledge is required in metalworking. Among other things, users should have knowledge of turning, a machining process in which the workpiece rotates and in so doing performs the main cutting movement. The cut metal is lifted off with the help of a firmly clamped tool and an advancing tool carriage. Milling is another metalworking fundamental. This is a metal-cutting process. Flat surfaces and contours can be produced with a milling tool. The interrupted cut is characteristic of milling. The rotation of the multi-bladed milling tool in relation to the firmly clamped workpiece results in chip removal. Another of the fundamentals is metal drilling. Drilling is a machining process for producing round holes. A metal-removing cutting motion is created as the tool performs a circular cutting motion and a straight-line feed motion. Materials science, i.e. the knowledge of materials such as non-ferrous metals or stainless steel and their properties, is also one of the basics of metalworking.

What do we need to bear in mind when working with metal?

Materials made of metal, e.g. profiles made of aluminium, iron, steel or stainless steel, are not always as easy to handle as wood due to their solid properties. When working with metal, e.g. drilling metal, drilling steel, sawing metal or polishing stainless steel, protective clothing should always be worn due to the increased risk of injury. Among other things, it must be noted that high temperatures can arise depending on the process involved, for example during soldering. In addition, the workpiece should always be firmly clamped and fixed to prevent injury.

Which tools are needed?

A wide variety of metal tools are required for metalworking, depending on the job These include for example an angle grinder, a belt grinder or a drill.

Drilling metal

When drilling metal (drilling steel, drilling non-ferrous metals, drilling stainless steel etc.), twist drills are used that have the necessary properties to guarantee good work progress. However, this also includes a drill or cordless drill that has the necessary speed range and torque. Special products in metalworking here are metal drills, steel drills or drills for stainless steel.

Sawing metal

Compared with wood saws, metal saws have a different cutting edge geometry, tooth shape and more teeth. These ensure that no problems arise when cutting through metal, steel or stainless steel when the metal is being sawn. Attention should also be paid to the cutting speed, and that the cut is cooled if necessary. A jigsaw, reciprocating saw or band saw with the appropriate saw blade can be used to saw metals. However, there are also special metal circular saws or iron saws that have been specially developed for this metalworking job.

Grinding metal

Sandpaper or sanding sponges can be used to grind metal. However, these are only suitable for smaller sanding jobs and the progress of the work is slower. Grinding machines such as angle grinders, random orbit sanders or straight grinders ensure faster progress and removal when grinding metal.